The average car buyer rarely considers what goes on under the skin of their vehicle of choice and what design processes took place to get it from a drawing to reality and, while the Bugatti Tourbillon hypercar is certainly not average in any way, shape or form, the intricate packaging philosophy behind the car makes for interesting reading.

The Tourbillon’s engineering narrative centres on holistic architecture and aerodynamic strategy, moving beyond individual components. Bugatti Rimac CEO Mate Rimac emphasised this interconnectedness: “When you develop a car, especially from scratch, you can never look at a single component individually without taking the whole context of the car into account.”

If it is something Exotic you are after – click here

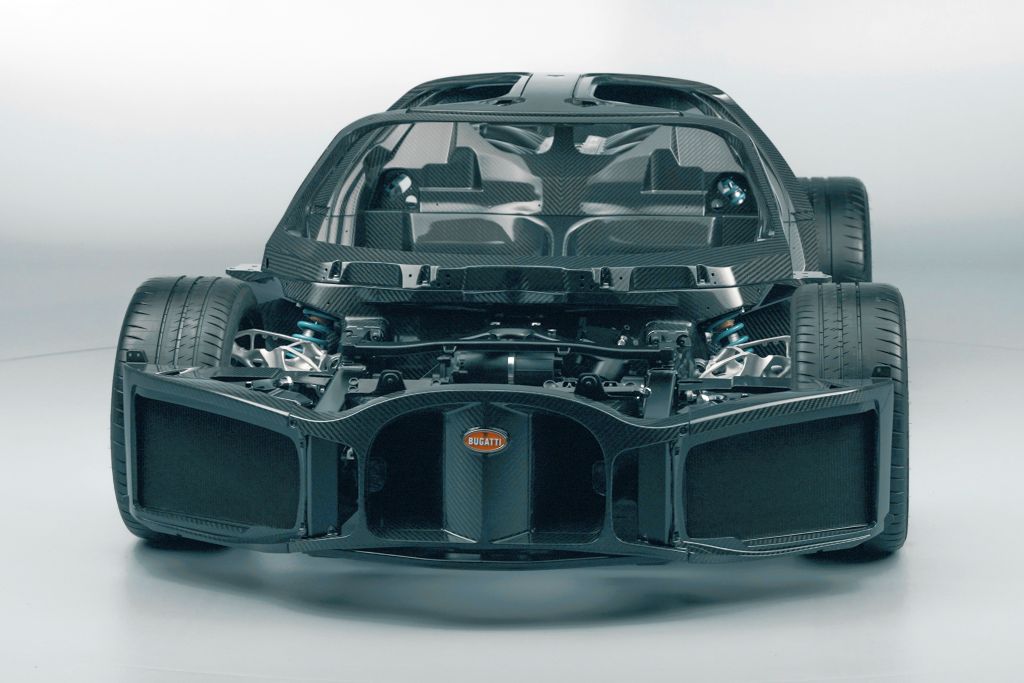

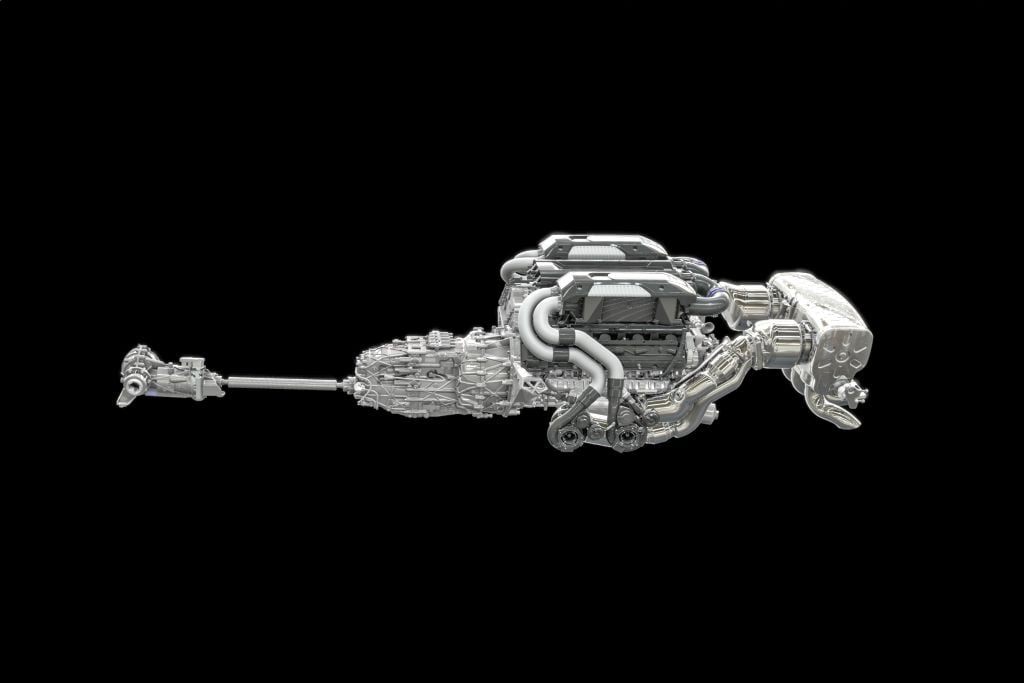

A central shift involves the newly developed V16 engine. Longer and narrower than its W16 predecessor, it is mounted at an angle within the chassis. This seemingly subtle adjustment yields significant implications, enabling engineers to incorporate exceptionally long Venturi channels within the diffuser system. These channels begin beneath the passenger cabin and extend nearly halfway along the vehicle’s length.

Functionally, these tunnels are vital for aerodynamic efficiency. They generate substantial downforce from beneath the car, reducing reliance on traditional wings. This method achieves necessary downforce levels with less aerodynamic drag, allowing the Tourbillon to reach its top speed without deploying the rear wing.

Crunch the numbers by using this handy Finance Calculator

This extensive underbody solution was facilitated by an innovative powertrain configuration. Departing from convention, the gearbox is positioned behind the V16 engine, not in front. The front axle receives power independently from two electric motors, eliminating any mechanical linkage between the combustion engine and the front wheels. A compact battery unit is situated between the front and rear motors, contributing to efficient space utilisation and optimised weight distribution.

This revised layout also enabled a reduction in the car’s frontal area, a critical factor for a hypercar targeting speeds beyond those achieved by the Chiron. Rimac highlighted its importance: “People sometimes forget total dynamic resistance of a car is the drag coefficient times the frontal area. So, it's important to reduce the frontal area, especially for a hypercar that goes the speeds that we do.”

Integration extends to the iconic Bugatti horseshoe grille at the front. More than a signature design element, it acts as a functional cooling interface. Airflow enters through the grille, passing the luggage compartment to cool the front electric axle, battery, and brakes. Cooling for the combustion engine is managed through intakes positioned left and right of the main grille.

We’ve got you covered – for the best insurance deal click here

The rear exemplifies Bugatti’s integration philosophy. Replacing a conventional solid crash beam, the Tourbillon’s rear diffuser incorporates two advanced 3D-printed metal structures specifically engineered to absorb crash energy.

Further design detail is found in the suspension. Components feature airfoil shapes and are partially exposed to airflow, enhancing aerodynamic efficiency. Traditional suspension parts would disrupt airflow; Bugatti countered this using 3D printing and AI-driven optimisation to create wishbones that are both strong and aerodynamically efficient.

Software and AI played a key role in refining component shapes. Engineers employed these tools to meticulously remove material, leaving only structurally essential elements. This approach, visible in areas like the upper suspension components, results in organic-looking microstructures designed for maximum strength with minimal weight.

Power up, gear up for the very best in preowned car, bakke or bikes deals - click here

From the angled V16 placement to the topology-optimised suspension, the Tourbillon’s packaging embodies Bugatti’s core philosophy. Each design decision prioritised the creation of a cohesive, integrated machine. Rimac concluded: “The Bugatti Tourbillon focuses on both individual components and how they work together to enhance to the overall car in terms of weight, packaging space, aerodynamic efficiency, downforce, performance. It was not an easy task for the team, but the result is outstanding.” The documentary episode offers a comprehensive look at this intricate engineering achievement.

More can be seen on YouTube in the series 'Bugatti: A New Era', that showcases how the automaker’s approach to balancing design, performance, and innovation reaches a new level in this model.

Colin Windell for Colin-on-Cars in association with

proudly CHANGECARS